If it were my airplane, I'd try to avoid breaking the wire bundle at the wing roots.

I'm flying rental machines that are 40+ years old that have never had the wings

off! Unless you KNOW that routine opening of a wire bundle is a good

thing to do (perhaps your airplane folds the wings and goes onto a trailer

between flights) then I'll suggest that you assemble the wings with long pigtails

of wire extending out the roots. Wire them into the ship's systems solid but

put about 6" of slack in the bundles at the roots. When and if you need to open

the bundles, go ahead and cut them. When the wings go back on, restore the bundles

with butt-splices. The slack wire at the roots will let you pull and replace

the wings perhaps 5-6 times by cutting out the butt splices before you need to

do anything like extend the wires.

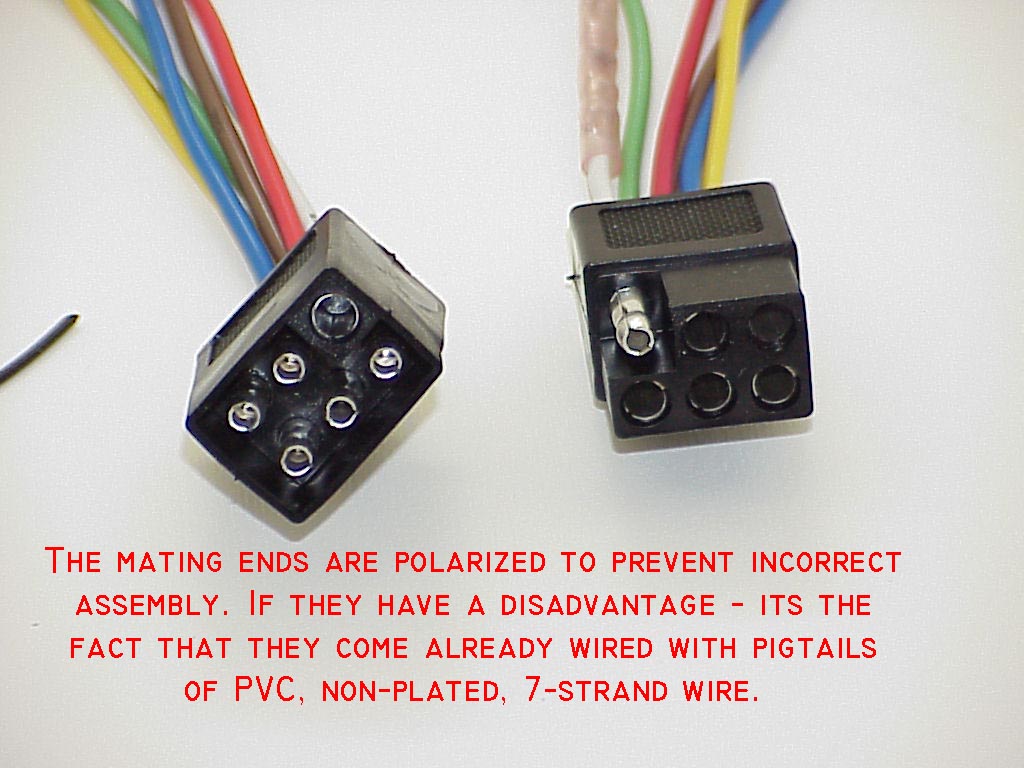

If you really gotta have wing-root disconnection of ship's wiring, consider

the technique below:

Click here to contact Bob at AeroElectric Connection

Click here to contact Bob at AeroElectric Connection