|

The "firewall" on an airplane wasn't named with any sense of

whimsy . . . 99.99% of the time, all it does is keep a blast of cold air out of

the cockpit. But on rare occasions, it is expected to stand between a fuel

fed fire and folks in the cockpit who are doing their best to survive

the experience.

Hundreds of thousands of single engine aircraft have been built in the past

100 years. Most were fabricated with some attention paid to the physics

of fire protection. Every firewall-sheet of stainless steel (or composite

material selected for it's fire resistance) is perfectly capable

of doing its job . . . as long as you don't cut holes in it. Unfortunately,

it's necessary for things forward of the firewall to be in communication with

things aft of the firewall. There are controls, fuel plumbing, instrumentation

and power generation wiring that must run between engine compartment and cockpit thus

requiring a certain number of HOLES in the firewall.

Penetrations of fuel and other fluid plumbing running through all

metal bulkhead fittings require little further consideration. For certified

airplanes, the FARs tell us that bulkhead feed through fittings of

steel or copper-alloy may be used with no concerns for compromising firewall

integrity. There are a variety of metal "eyeball"

fittings available for easing the transition of throttle, prop, mixture and

cowl flap controls at odd angles. This leaves us with the "soft" lines such

as wires and perhaps small fluid lines for pressure instrumentation.

|

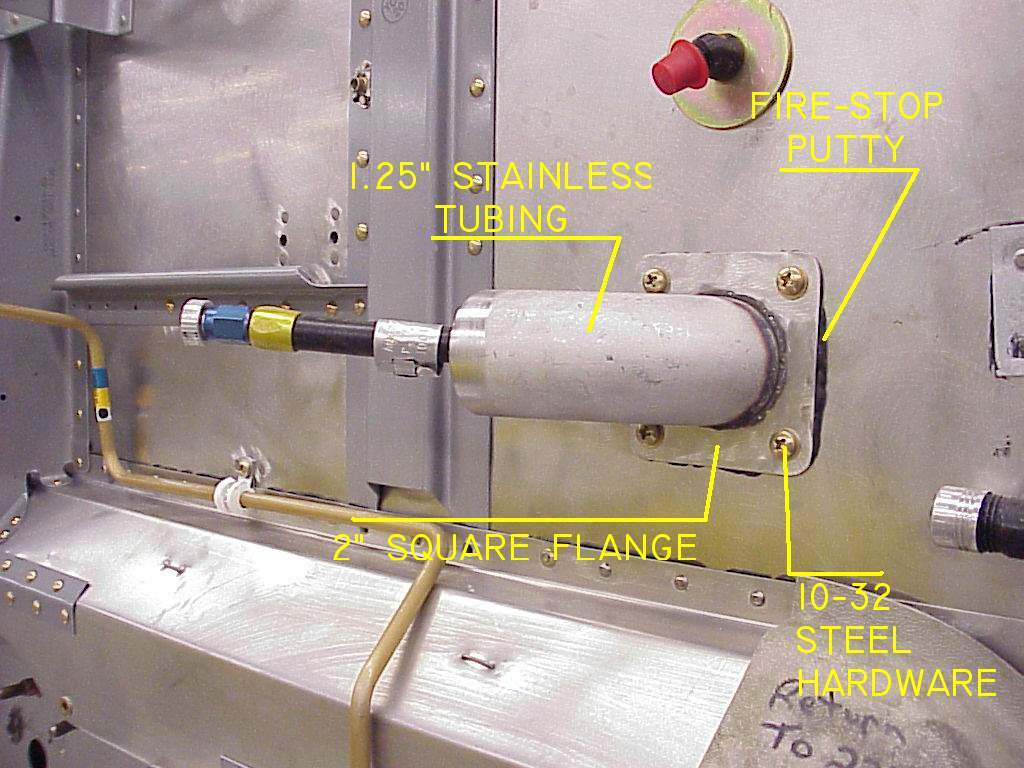

Click here for larger image A visit with

camera in hand to a production line for certified piston aircraft allowed me

to record and share a fabrication technique for soft penetration. This technique

has a long history of laboratory testing for effectiveness, production line

convenience, and field maintainability. In this case, all of the wiring comes

through a single, fairly large penetration fitting . . . but there's no reason why

multiple, smaller fittings wouldn't work too . . . Here we see how a stainless weldment bolted to the firewall with steel hardware provides the structural component of a transition for wires and other relatively "soft" materials running between cockpit and engine compartment. Note generous flange area outside the tube to flange interface that is sealed with fire-stop when the flange is bolted into place. |

|

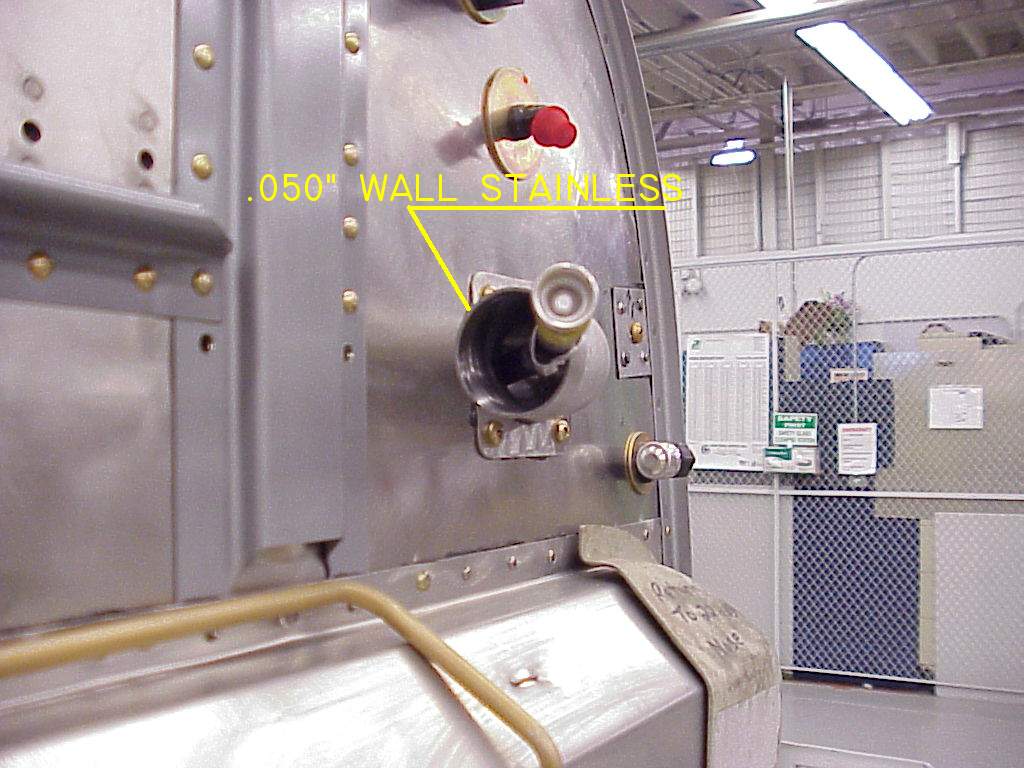

Click here for larger image The fittings

for this airplane are made from 0.050" stainless. Thickness and attaching

geometry are a function of how much support the fitting needs to provide for

the bundle of transitioning wires and tubes. The material shown here is pretty

hefty stuff and may have been selected as handier to weld than thinner material.

Drawings for other firewall fittings used in this same factory show materials

as thin as 0.020" thick. Builders can certainly experiment with thinner material and alternative joining techniques. Periodic inspections will show whether or not there are issues of mechanical robustness . . . not strong enough, they'll simply come apart. Given that fires are VERY rare, the failure of an experimental fitting doesn't represent a great threat as long as you do reasonably complete inspections during normal P/M activities . . . like every oil change. The worst thing that happens is that you have to build a more robust transition fitting and replace the broken one.

|

|

|

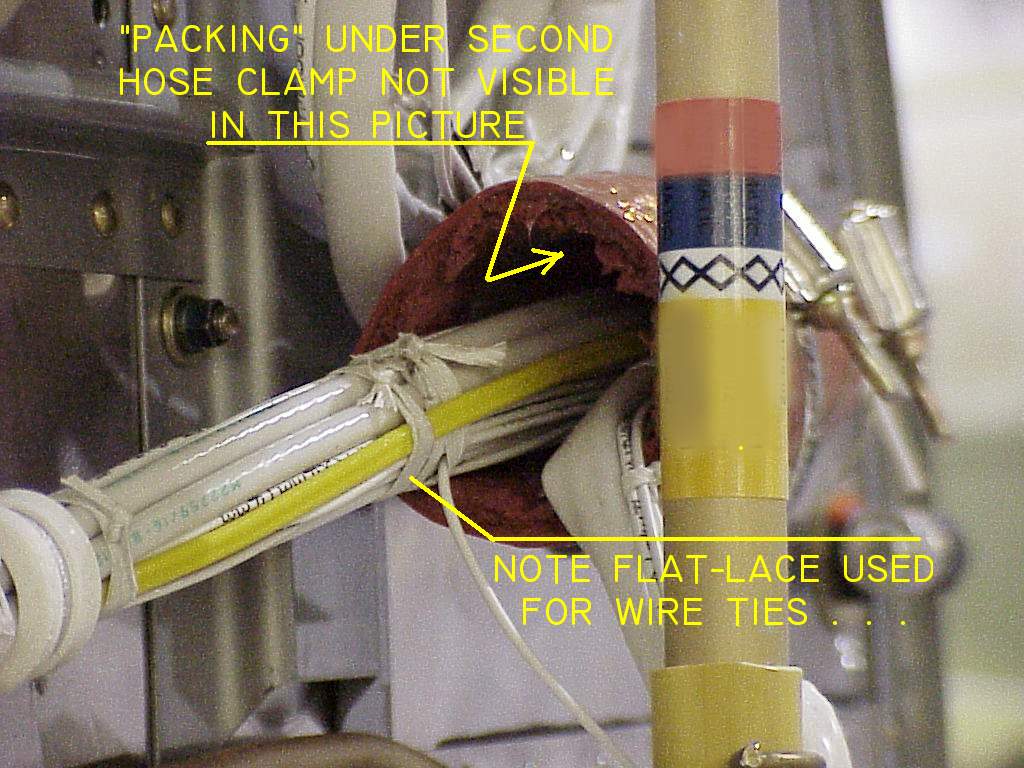

Click here for larger image Looking

up the business end of the finished transition. What's not visible in this

view is the packing placed around wires so that the second hose clamp

doesn't have to put a super-crush on the fire sleeve . . . . more on

this later.

|

|

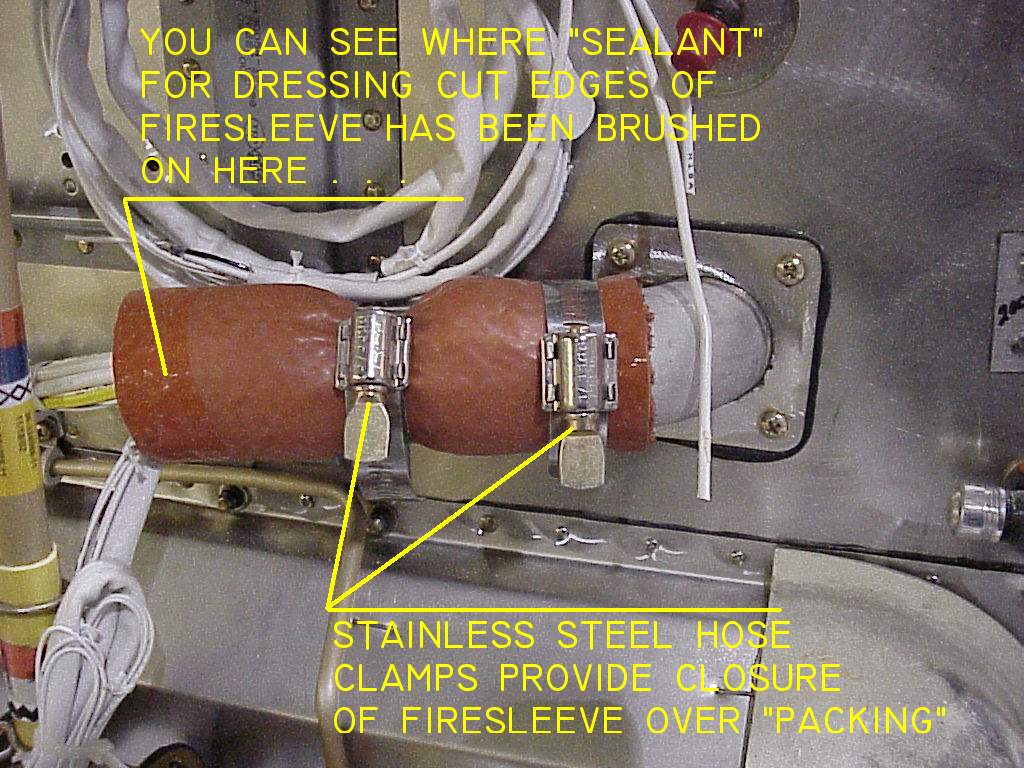

Click here for larger image The flight-ready

firewall penetration. A second hose clamp brings the fire sleeve down for

a snug fit on the wire bundle. A filler wrap around a wire bundle much

smaller than the i.d. of the fire sleeve makes for a better seal with

less crush under the second hose clamp . . .

|

|

|

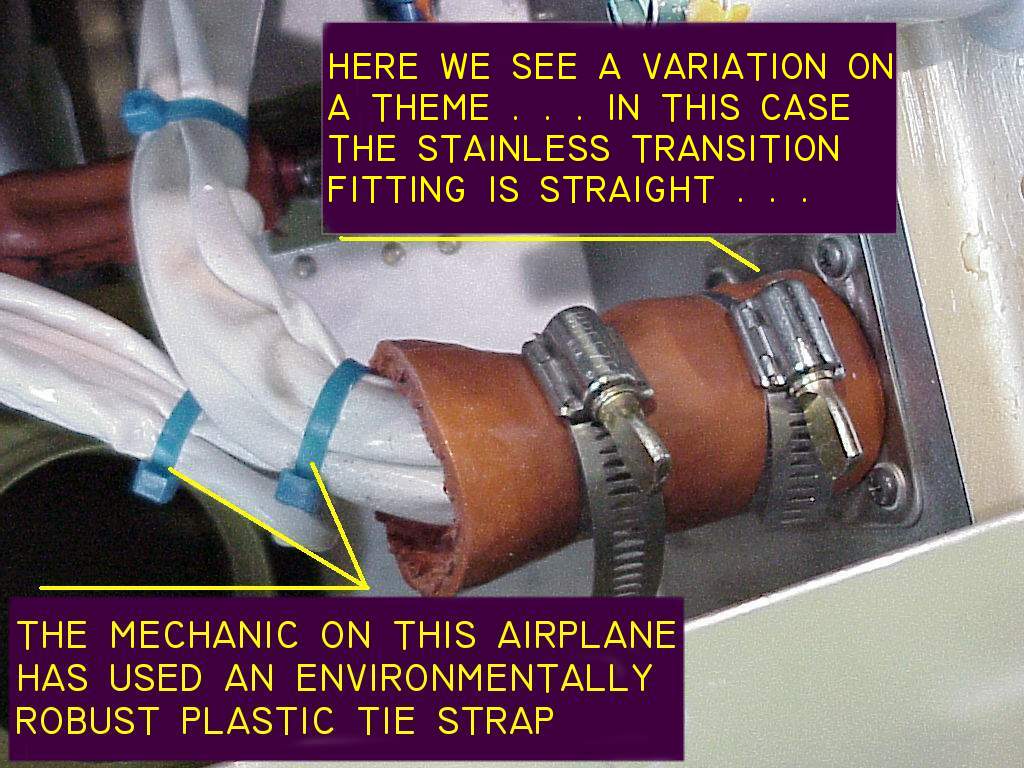

Click here for larger image On another

airplane, we find a similar technique except that the stainless steel

firewall fitting is straight, no 90-degree bend. Otherwise, installation and

functionality is same as shown above.

|

|

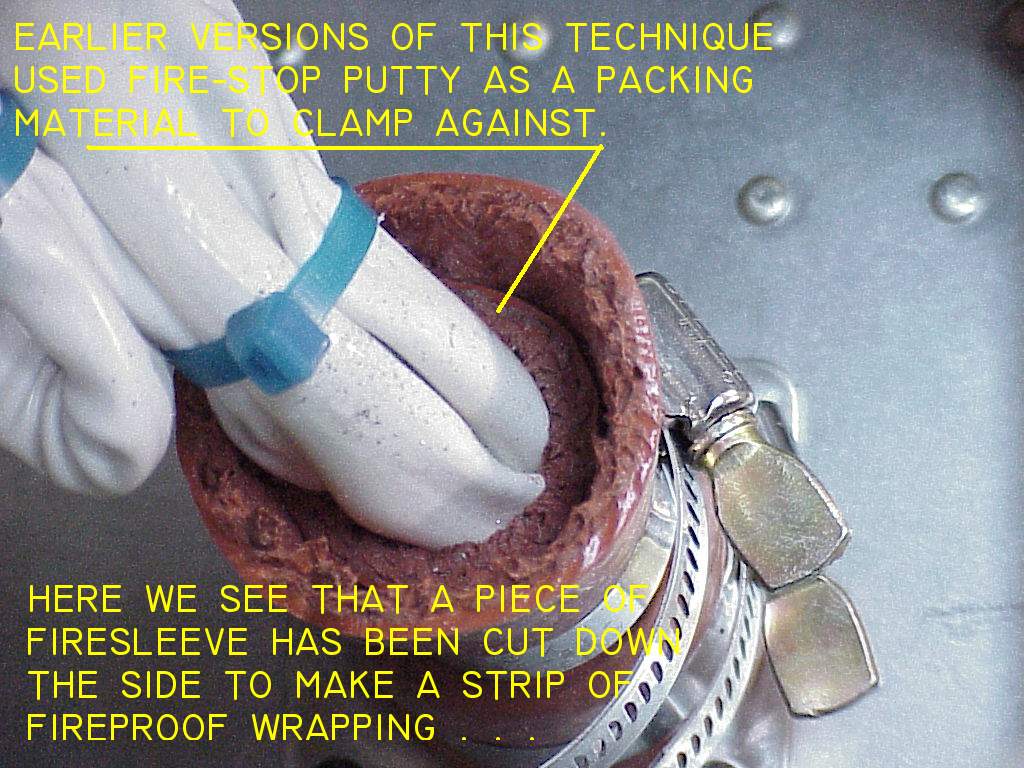

Click here for larger image This view

illustrates an interesting packing material used to build up the wire

bundle size. A piece of fire sleeve was cut down the side and made into

a strip of wrapping filler. Note that all exposed edges of the fire sleeve

are "doped" with the recommended sealer to preclude entry of moisture

and to keep the edges from fraying . . .

|

|

Click here to contact Bob at AeroElectric Connection Click here to contact Bob at AeroElectric Connection |